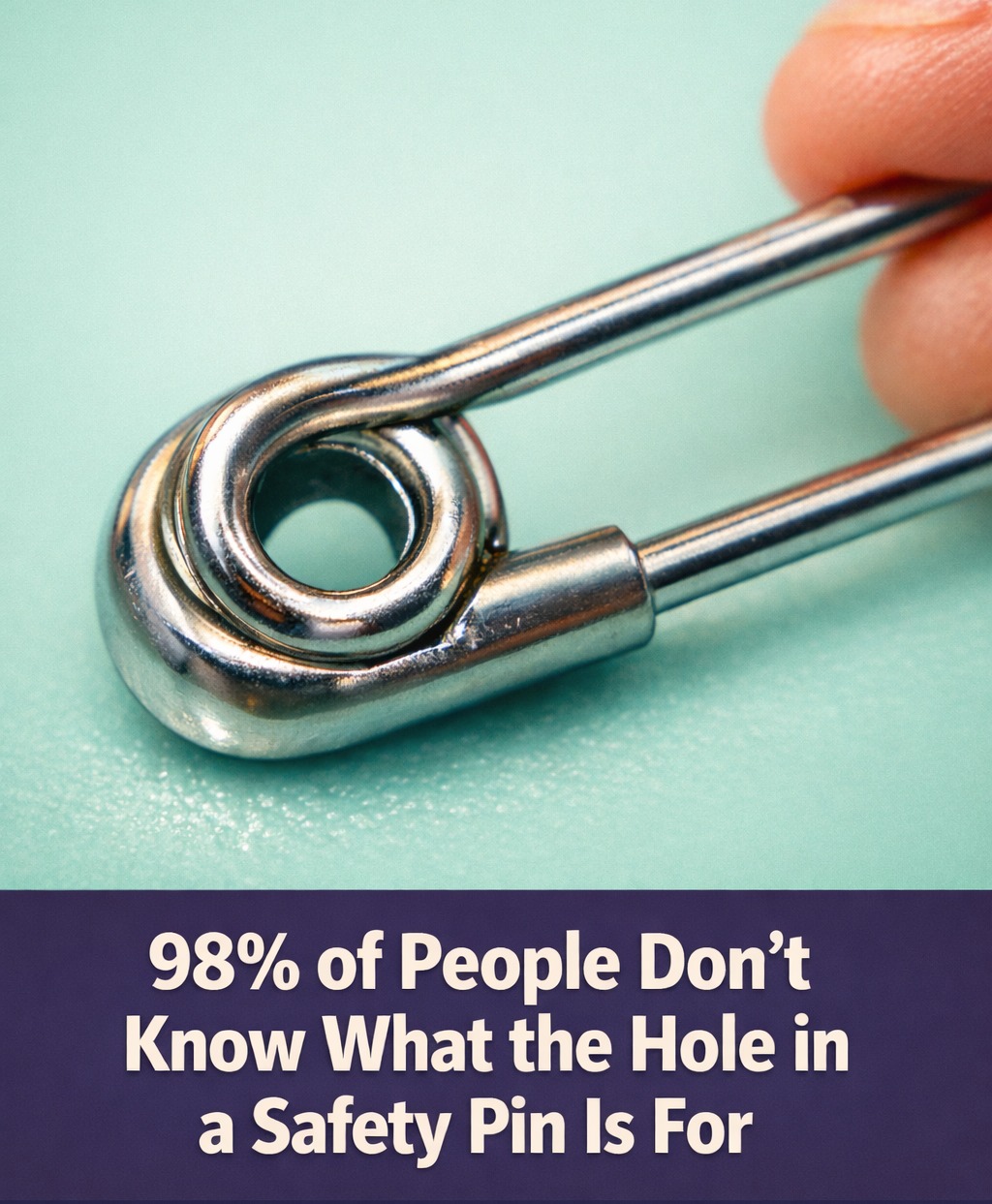

* Near the **hinged end** of the safety pin

* Just below or beside the coiled spring

* Typically circular and very small

It’s not random. It’s placed precisely where it needs to be to support the pin’s function.

## The Primary Purpose: Managing Spring Tension

The most important reason the hole exists is **spring control**.

A safety pin works because of the **coiled wire spring** at one end. When you open the pin, you twist the wire slightly, storing energy. When you close it, that stored energy pushes the pin back into its clasp, keeping it securely shut.

The tiny hole helps:

* Anchor the wire during manufacturing

* Maintain consistent tension in the spring

* Prevent the wire from slipping or misaligning

Without that hole, the pin would lose strength more easily or fail to close properly.

—

## A Crucial Part of the Manufacturing Process

1. Bent into shape

2. Coiled to form the spring

3. Cut and finished

The tiny hole acts as a **guide point** during this process.

Manufacturers use it to:

* Secure the wire while forming the coil

* Control the tightness of the spring

* Ensure uniformity across millions of pins

This makes the safety pin:

* Stronger

* More durable

* Consistent in performance

That tiny hole is essentially a precision tool mark with a permanent purpose.

## Preventing Structural Weakness

It might seem counterintuitive, but adding a hole can actually make a design *more* reliable.

By giving the wire a controlled place to settle:

* Stress is distributed more evenly

* The risk of metal fatigue is reduced

* The spring lasts longer through repeated use

Without that hole, tension could concentrate in one spot, making the pin more likely to deform or snap over time.

—

## Does the Hole Serve Any Purpose for the User?

Indirectly, yes.

While most users never interact with the hole, it contributes to:

* How tightly the pin stays closed

* How smoothly it opens

* How long it remains functional

Some niche uses also take advantage of it:

* Attaching thread or fine wire for temporary hanging

* Helping stabilize the pin when sewing in tight spaces

But its main benefit is invisible—**reliability**.

—

## Why Not Just Leave It Out?

Good question.

If the hole were unnecessary, manufacturers would remove it to save time and materials. But it remains because:

* It improves consistency

* It reduces defects

* It increases lifespan

* It keeps the spring aligned

Even tiny inefficiencies matter when producing billions of units worldwide.

—

## Similar “Hidden Features” in Everyday Objects

The safety pin isn’t alone in hiding clever design details.

Examples include:

* The hole in pen caps (to reduce choking risk)

* The ridge in bottle caps (to indicate tampering)

* The extra drawer under ovens (originally for warming)

* The small holes in cutting boards (for hanging and drainage)

These features often go unnoticed—but they exist for very specific reasons.

—

## Why Simple Objects Often Have the Smartest Design

The safety pin is a perfect example of **elegant engineering**.

It hasn’t changed much in over 170 years because:

* It already works exceptionally well

* Its design balances simplicity and function

* Every part serves a purpose

The tiny hole may seem insignificant, but removing it would compromise the whole system.

—

## Why This Tiny Detail Still Matters Today

In a world obsessed with innovation, the safety pin reminds us that:

* Good design doesn’t always need upgrades

* Small details can have huge impact

* Function often matters more than appearance

That tiny hole represents thousands of design decisions refined over generations.

—

## Final Thoughts: Big Purpose, Small Hole

The next time you pick up a safety pin, take a second look.

That tiny hole isn’t a flaw.

It isn’t decoration.

And it isn’t accidental.

It’s a quiet reminder that even the most ordinary objects are often far more thoughtful than they appear.

Sometimes, the smallest details hold the biggest purpose—and the safety pin proves it every time.