* Smoking

* Drying

* Fermenting

* Cooking

* Cooling

During these stages, sausages are commonly **hung vertically** on racks. Hanging allows for:

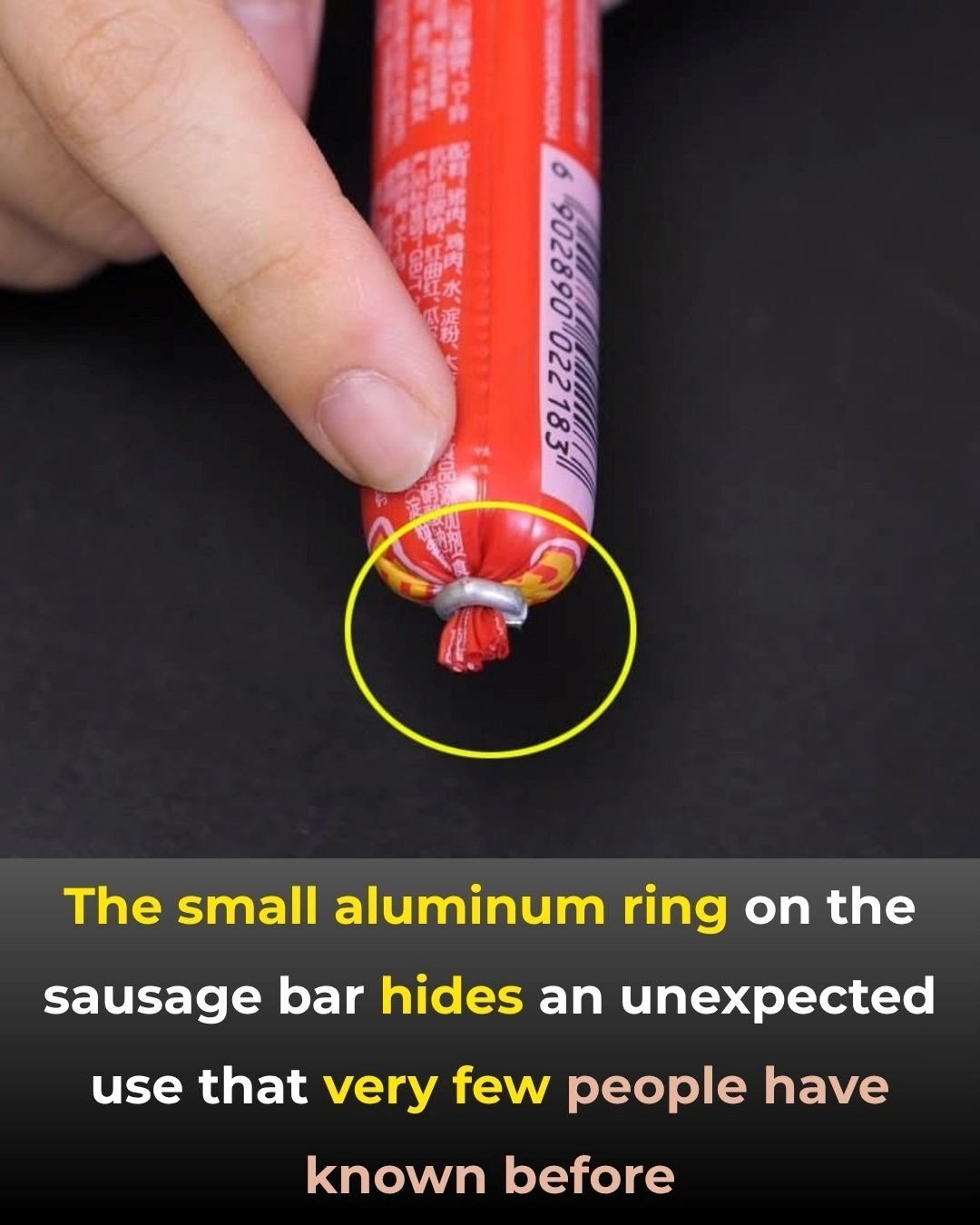

The aluminum ring serves as a **strong, heat-resistant loop** that can support the weight of the sausage without tearing the casing. It’s far more reliable than tying a knot in the casing alone, especially when sausages are handled in large quantities.

This hanging method dates back centuries, long before modern factories existed. Traditional sausage makers used string, hooks, or metal loops to hang meats in smokehouses and curing rooms. The aluminum ring is simply a modern, standardized evolution of that practice.

—

## **Why Aluminum?**

You might wonder why aluminum is used instead of plastic or another metal.

Aluminum offers several advantages:

* **Heat resistance** – It holds up during smoking and cooking.

* **Lightweight** – It doesn’t add unnecessary weight to the product.

* **Corrosion resistance** – It won’t rust or contaminate the meat.

* **Food-safe** – Aluminum is widely approved for food contact.

* **Affordable** – Cost-effective for mass production.

Plastic alternatives often can’t withstand high temperatures, while steel would be heavier and more expensive. Aluminum hits the sweet spot.

## **A Secondary Purpose: Structural Integrity**

The ring also helps maintain **consistent shape and sealing** at the end of the sausage casing.

When meat is packed tightly into a casing, pressure builds — especially during cooking or drying. The aluminum ring reinforces the sealed end, preventing:

* Splitting

* Leaks

* Uneven shrinkage

This ensures that every sausage stick looks uniform and professional, which matters more than you might expect in commercial food production.

Visual consistency plays a huge role in consumer trust. A broken casing or irregular end can make a perfectly safe product look unappetizing.

—

Here’s the part that surprises most people: **the ring stays on because removing it would actually cause more problems than leaving it in place.**

Once the sausage is finished and packaged, removing the ring would:

* Risk tearing the casing

* Compromise the seal

* Introduce unnecessary handling (increasing contamination risk)

* Slow down production

* Increase costs

Since the ring doesn’t interfere with eating the sausage and poses no safety issue, manufacturers simply leave it in place.

In other words, the ring has already done its job — but taking it off would do more harm than good.

—

## **The Hidden Consumer Use Most People Don’t Know**

Here’s where things get interesting.

While manufacturers include the aluminum ring for production reasons, consumers can actually **use it too** — and very few people realize this.

### **1. A Built-In Hanging Hook**

The ring allows you to hang the sausage stick while eating it.

This may sound trivial, but it’s surprisingly practical in situations like:

* Hiking

* Camping

* Fishing

* Working outdoors

* Road trips

You can hang the sausage on:

* A backpack strap

* A nail or hook

* A branch

* A belt loop

This keeps the food off dirty surfaces and frees up your hands.

In outdoor and survival communities, this trick has quietly existed for years — but it’s rarely talked about in mainstream food culture.

—

### **2. A Grip for Clean Eating**

Another clever use: the ring acts as a **handle**.

Holding the sausage by the ring keeps your fingers clean, especially when:

* The sausage is greasy

* You’re wearing gloves

* You don’t have napkins

Some people even eat most of the sausage while holding the ring and discard it at the end — reducing mess and making cleanup easier.

—

### **3. Easy Opening and Control**

The ring gives you a solid anchor point when tearing open the casing or wrapper.

Instead of squeezing the sausage and risking it slipping out of your hands, you can:

* Hold the ring steady

* Pull the wrapper down smoothly

* Maintain control

This small advantage becomes obvious when you’re opening a sausage stick with cold hands, wet fingers, or while multitasking.

—

## **Why So Few People Know About This**

Despite its usefulness, the aluminum ring’s purpose isn’t widely known for a few reasons:

### **1. It’s Never Explained**

Manufacturers rarely explain the ring on packaging. From a marketing standpoint, it’s unnecessary — and drawing attention to production hardware could even confuse consumers.

### **2. Modern Convenience Culture**

Most people eat sausage sticks quickly and casually. There’s little incentive to analyze a detail that doesn’t obviously affect taste or convenience.

### **3. Lost Traditional Knowledge**

The hanging and curing traditions behind the ring come from old-world meat preservation practices. As food production became industrialized, the “why” behind many features disappeared from public knowledge.

—

## **Is It Safe to Eat Sausage with the Ring Attached?**

Yes — as long as you remove it before eating the last bite.

The aluminum ring is **food-safe**, but it’s not meant to be consumed. It should be discarded once the sausage is finished.

Manufacturers design it to stay attached firmly during production and handling, so it won’t accidentally fall into the food. That’s why you’ll almost always find it still attached at the end.

—

## **Why This Tiny Detail Matters**

At first glance, the aluminum ring seems insignificant. But it’s actually a perfect example of how **thoughtful design hides in plain sight**.

It represents:

* Centuries of food preservation knowledge

* Efficient industrial manufacturing

* Practical consumer usability

* Minimalist design that solves multiple problems at once

In an era where products are often over-engineered or overloaded with features, the sausage stick ring stands out as a quiet success — a small solution doing exactly what it needs to do.

—

## **Will the Ring Ever Disappear?**

Unlikely.

Some manufacturers have experimented with alternative sealing methods, but the aluminum ring remains popular because it’s:

* Reliable

* Cheap

* Proven

* Compatible with existing equipment

As long as sausage sticks are smoked, dried, and mass-produced the way they are today, that tiny ring will probably remain part of the process.

—

## **Final Thoughts**

The next time you pick up a sausage stick and notice that small aluminum ring, you’ll know the truth: it’s not just packaging clutter.

It’s a tool — one with roots in traditional meat curing, modern manufacturing efficiency, and surprisingly practical everyday use.